Are you tired of that unpleasant odor coming from your sump pump? Don’t worry, because we’ve got the solution for you! In this article, we’ll show you exactly how to get rid of sump pump odor for good. Whether you’re dealing with a musty smell or a foul sewage odor, our step-by-step guide will help you eliminate it and create a fresh and odor-free environment in your basement.

We understand how frustrating it can be when your sump pump starts emitting unpleasant smells. Not only does it make your basement uncomfortable, but it can also indicate a deeper issue with your sump pump system. That’s why it’s crucial to address the odor problem as soon as possible.

Using our expert tips and proven methods, you’ll be able to identify the cause of the odor and take the necessary steps to eliminate it. From cleaning and disinfecting your sump pump to preventing future odors, we’ve got you covered. Say goodbye to that unpleasant smell and hello to a fresh and clean basement!

Remember, a well-functioning sump pump should not emit any odor. So, let’s dive in and banish that sump pump odor once and for all!

Understanding the causes of sump pump odor

To effectively tackle sump pump odor, it’s important to understand its underlying causes. There can be several reasons why your sump pump is emitting unpleasant smells. One common cause is the presence of stagnant water in the sump pit. When water sits for an extended period, it can develop a musty odor. Another cause could be a faulty or improperly installed sump pump, which can lead to sewage odors.

Additionally, mold and mildew growth can contribute to sump pump odor. These fungi thrive in damp environments and can release a pungent smell. Finally, if your sump pump is constantly running, it may not have enough time to dry out, leading to the growth of bacteria that produce foul odors.

The importance of addressing sump pump odor

Ignoring sump pump odor can have serious consequences. Not only does it make your basement an unpleasant space to be in, but it can also indicate potential issues with your sump pump system. A well-functioning sump pump should not emit any odor, so if you notice a persistent smell, it’s crucial to take action.

Sump pump odor can be a sign of water damage, mold growth, or even a malfunctioning sump pump. These issues can lead to costly repairs and potential health hazards if left unaddressed. By tackling the odor problem early on, you can prevent further damage and ensure the longevity of your sump pump system.

Common DIY methods to eliminate sump pump odor

If you’re looking to tackle sump pump odor on your own, there are several DIY methods you can try. The first step is to inspect and clean the sump pit. Remove any debris, dirt, or standing water from the pit using a shop vacuum or a bucket. It’s important to wear protective gloves and a mask to avoid contact with potentially harmful substances.

Once the pit is clean, you can create a homemade cleaning solution using a mixture of water and bleach. Use a scrub brush to thoroughly clean the pit, ensuring you reach all corners and crevices. After scrubbing, rinse the pit with clean water to remove any remaining bleach residue.

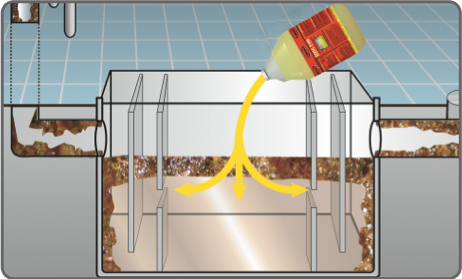

Another effective DIY method is to use vinegar to eliminate sump pump odor. Vinegar is a natural disinfectant that can help neutralize odors. Mix equal parts vinegar and water and pour it into the sump pit. Allow the mixture to sit for a few hours before flushing it out with clean water.

Using natural remedies to get rid of sump pump odor

If you prefer to use natural remedies, there are several options available to you. Baking soda is a versatile and affordable natural deodorizer. Sprinkle baking soda directly into the sump pit to absorb odors. Leave it overnight and then vacuum or sweep it out the next day.

Charcoal is another effective natural remedy for sump pump odor. Place a few pieces of activated charcoal in a mesh bag and hang it near the sump pit. Charcoal has excellent odor-absorbing properties and can help eliminate the unpleasant smell.

You can also use essential oils to mask sump pump odor. Add a few drops of your favorite essential oil, such as lavender or lemon, to a cotton ball and place it near the sump pit. The pleasant scent of the essential oil will help mask any lingering odors.

Professional solutions for sump pump odor removal

If the DIY methods mentioned above don’t completely eliminate the sump pump odor, it may be time to consider professional solutions. In some cases, a faulty or outdated sump pump may need to be replaced. Additionally, for an effective and eco-friendly solution, consider using Brofloat, a floating citrus-based degreaser and deodorizer. Brofloat is designed to break down and eliminate unpleasant odors in sump pump systems.

You can learn more about this product and its benefits by clicking here

Brofloat not only neutralizes odors but also helps in maintaining a clean and efficient sump pump system. Its citrus-based formula is environmentally friendly and safe for use in residential spaces. By incorporating Brofloat into your sump pump maintenance routine, you can enjoy a fresher and more pleasant basement environment, ensuring the longevity and effectiveness of your sump pump system.

Preventing sump pump odor in the future

Once you’ve successfully eliminated the sump pump odor, it’s important to take preventive measures to ensure it doesn’t return. Regular maintenance is key to keeping your sump pump system odor-free. Here are a few tips to help you prevent sump pump odor in the future:

1. Check your sump pump regularly for any signs of malfunction or damage. Look for leaks, strange noises, or excessive vibration.

2. Clean the sump pit and remove any debris or standing water on a regular basis.

3. Install a sump pump cover to prevent odors from escaping and to keep out debris and pests.

4. Consider installing a backup sump pump system to ensure continuous operation even during power outages.

5. Keep the surrounding area of the sump pump clean and free from clutter to promote proper air circulation.

By following these preventive measures, you can maintain a fresh and odor-free basement and avoid any future issues with your sump pump system.

Maintaining and cleaning your sump pump to prevent odor

Regular maintenance and cleaning are essential to prevent sump pump odor. Here are some steps you can take to maintain and clean your sump pump:

1. Test your sump pump regularly by pouring water into the pit and ensuring it activates properly.

2. Clean the sump pit at least once a year to remove any debris or sediment that may have accumulated.

3. Inspect the discharge pipe and make sure it is clear of any obstructions or clogs.

4. Check the float switch to ensure it is functioning correctly. This switch is responsible for activating the sump pump when the water level rises.

5. Consider installing a sump pump alarm that will alert you if the water level in the pit becomes too high.

By following these maintenance and cleaning tips, you can extend the lifespan of your sump pump and prevent any unpleasant odors from developing.

Signs of a malfunctioning sump pump that may contribute to odor

Sump pump odor can be an indication of a malfunctioning sump pump. It’s essential to be aware of the signs that your sump pump may not be functioning properly. Here are a few signs to watch out for:

1. Excessive noise: If your sump pump is making loud or unusual noises, it may be a sign of a mechanical issue.

2. Constant running: A sump pump that is constantly running even when there is no significant water accumulation may indicate a problem with the float switch or the pump itself.

3. Inconsistent operation: If your sump pump fails to activate when water levels rise or if it turns on and off frequently, it may be a sign of a malfunctioning float switch.

4. Visible leaks: Any signs of water leakage around the sump pump or the discharge pipe could be an indication of a faulty seal or a cracked pump housing.

If you notice any of these signs, it’s important to address the issue promptly to prevent further damage and potential odor problems.

Frequently asked questions about sump pump odor

1. Can a sump pump emit a foul sewage smell?

Yes, a foul sewage smell can indicate a problem with your sump pump system, such as a malfunctioning check valve or a broken sewer line.

2. How often should I clean my sump pump?

It’s recommended to clean your sump pump at least once a year to prevent odors and ensure optimal performance.

3. Can mold and mildew cause sump pump odor?

Yes, mold and mildew growth can contribute to sump pump odor. It’s important to address any signs of mold or mildew promptly.

4. Why is my sump pump constantly running?

A sump pump that is constantly running may indicate a problem with the float switch or a high water table in your area.

5. How long does a sump pump typically last?

The lifespan of a sump pump can vary depending on various factors, but on average, a sump pump can last anywhere from 7 to 10 years.

Conclusion: Enjoying a fresh and odor-free basement with a properly functioning sump pump

In conclusion, sump pump odor is a common issue that can be easily addressed with the right knowledge and tools. By understanding the causes of sump pump odor and taking preventive measures, you can enjoy a fresh and odor-free basement.

Remember, regular maintenance, cleaning, and inspection are essential to ensure your sump pump operates efficiently and keeps your basement dry and odor-free. If DIY methods don’t completely eliminate the odor, don’t hesitate to seek professional help to address any underlying issues with your sump pump system.

Say goodbye to that unpleasant smell and hello to a fresh and clean basement! With our expert tips and proven methods, you can banish sump pump odor for good and create a comfortable living space that you and your family can enjoy.